progressive alloys technology & equipment production

what we offer

Equipment & Technology for production capacity from 1,000 tpyr to 5,000 tpyr.

Rod diameter from 8.0 mm to 30.0 mm.

According to the Rautomead 2023 Alloys List, progressive alloys include:

| Progressive Alloys | CuCr | Copper, chrome |

| CuZr | Copper, zirconium | |

| CuCrZr | Copper, chrome, zirconium | |

| CuCrZrP | Copper, chrome, zirconium, phosphorus | |

| CuFe | Copper, iron | |

| CuFeTiMg | Copper, iron, titanium, magnesium | |

| CuMn | Copper, manganese | |

| CuMnNi | Copper, manganese, nickel | |

| CuSP | Copper, sulphur, phosphorus | |

| CuNiSP | Copper, nickel, sulphur, phosphorus | |

| CuTi | Copper, titanium |

This continuous casting equipment incorporates Rautomead Sealed Lid (RSL) furnace technology developed specifically for processing aggressive alloys and alloys containing elements susceptible to rapid oxidation. This includes copper chrome zirconium alloys.

Customer reference installations located in Japan, Europe and China.

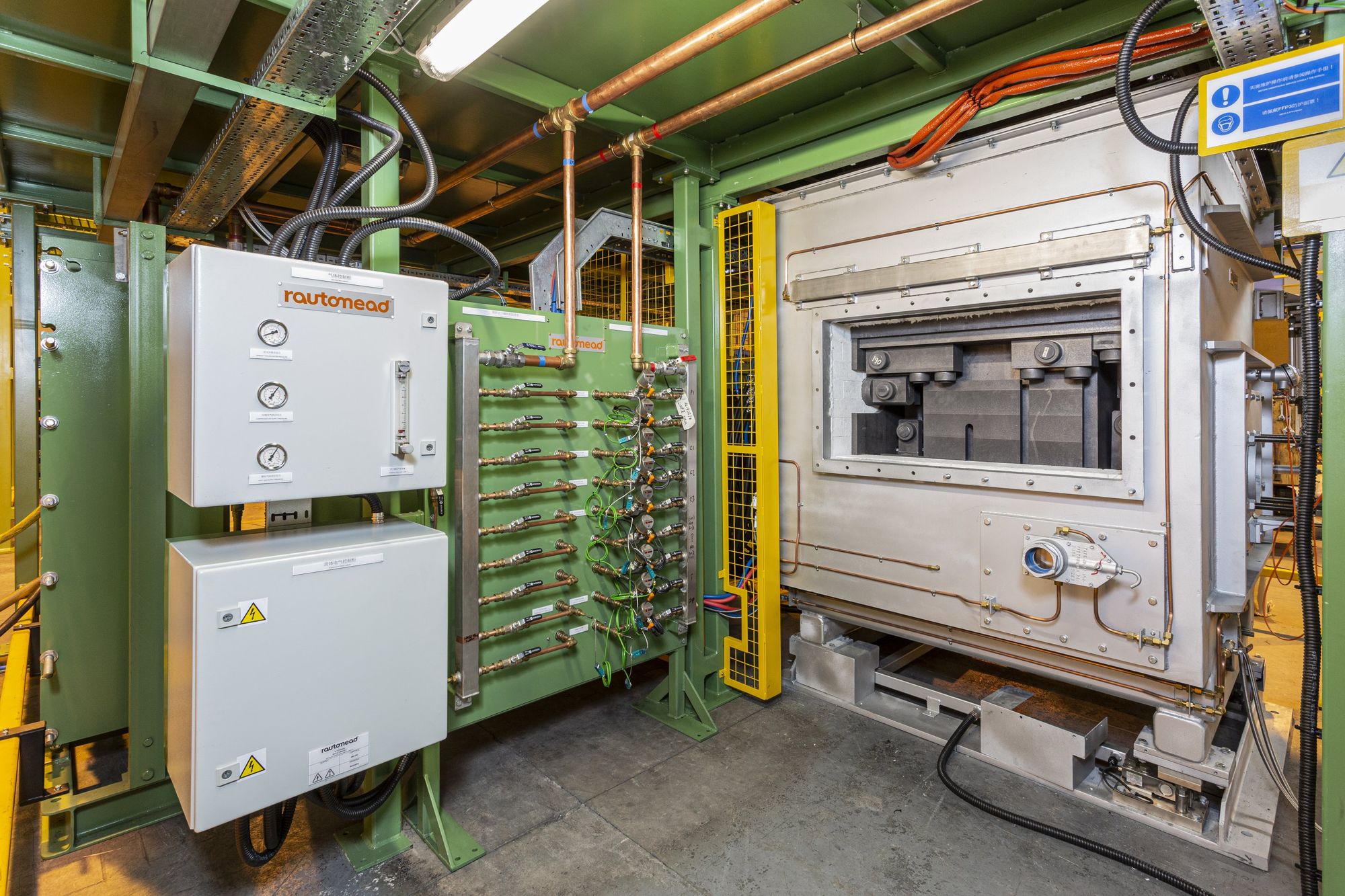

Example of Rautomead Production technology for progressive alloys

|

|

| RSL 1400 furnace elements & fluidics | RSL 1400 platform above rod feed |

features

- precise, adjustable, withdrawal pulse motion control

- resistance heating

- sealed lid

- graphite crucible

- automated composition control by cored wire and copper rod feed mechanisms

- controls: Omron, Siemens or Allen Bradley

The following global companies use Rautomead technology for progressive alloys -

|

|

|

| Lamifil | Shaanxi Sirui Advanced Materials Co. Ltd | Ningbo Jintian Copper (Group) Co. Ltd |